Wikipedysta:Leafnode/Główne silniki promu kosmicznego: Różnice pomiędzy wersjami

m piksele |

translation, Automatic translation przy użyciu AWB (0) |

||

| Linia 4: | Linia 4: | ||

|podpis_obrazka=Space Shuttle Main Engine test firing- the bright area at the bottom of the picture is a [[Mach disk]] |

|podpis_obrazka=Space Shuttle Main Engine test firing- the bright area at the bottom of the picture is a [[Mach disk]] |

||

|nazwa=Silnik główny promu kosmicznego |

|nazwa=Silnik główny promu kosmicznego |

||

|kraj=[[United States]] |

|kraj=[[Stany Zjednoczone|United States]] |

||

|producent=[[Pratt & Whitney Rocketdyne]] |

|producent=[[Pratt & Whitney Rocketdyne]] |

||

|użycie=[[Space Transportation System]] |

|użycie=[[Space Transportation System]] |

||

| Linia 25: | Linia 25: | ||

'''Główne silniki promu kosmicznego''' ([[język angielski|ang.]] ''Space Shuttle Main Engines'' - '''SSME''') to trzy silniki wielokrotnego użytku [[Orbiter STS|orbitera]] [[wahadłowiec kosmiczny|promu kosmicznego]]. Każde wyniesienie zespołu wahadłowca jest wspomagane przez trzy z zasobu czternastu silników stosowanych przez [[NASA]] w [[Space Transportation System|systemie transportu kosmicznego]]<ref>{{Cytuj stronę |url=http://www.nasa.gov/pdf/361842main_15%20-%20Augustine%20Sidemount%20Final.pdf |title=Shuttle-Derived Heavy Lift Launch Vehicle |author=John Shannon |date=June 17, 2009}}</ref>. Po każdym locie silniki były demontowane z orbitera, poddawane inspekcji i odnawianiu w celu przygotowania do kolejnego lotu. Silnik posiada także przemysłowe oznaczenie '''RS-24''' lub '''RS-25'''. |

'''Główne silniki promu kosmicznego''' ([[język angielski|ang.]] ''Space Shuttle Main Engines'' - '''SSME''') to trzy silniki wielokrotnego użytku [[Orbiter STS|orbitera]] [[wahadłowiec kosmiczny|promu kosmicznego]]. Każde wyniesienie zespołu wahadłowca jest wspomagane przez trzy z zasobu czternastu silników stosowanych przez [[NASA|NASA]] w [[Space Transportation System|systemie transportu kosmicznego]]<ref>{{Cytuj stronę |url=http://www.nasa.gov/pdf/361842main_15%20-%20Augustine%20Sidemount%20Final.pdf |title=Shuttle-Derived Heavy Lift Launch Vehicle |author=John Shannon |date=June 17, 2009}}</ref>. Po każdym locie silniki były demontowane z orbitera, poddawane inspekcji i odnawianiu w celu przygotowania do kolejnego lotu. Silnik posiada także przemysłowe oznaczenie '''RS-24''' lub '''RS-25'''. |

||

W ramach programu Space Transportation System wyprodukowana została całkowita liczba czterdziestu sześciu silników wielokrotnego użytku, z których do każego lotu były używane trzy<ref name=forum>KSC booklet, Quote: "Since the first Space Shuttle launch on April 12, 1981, 42 different SSMEs have successfully demonstrated the performance, safety, and reliability of the world's only reusable liquid-fuel rocket engine.", [http://www.collectspace.com/ubb/Forum30/HTML/000409.html source]</ref>. NASA planuje zachowanie od 14 do 16 silników w wersji Block II w celu potencjalnego ich wykorzystania w przyszłych, jeszcze niezdefiniowanych projektach<ref name=aw20110329/>. |

W ramach programu Space Transportation System wyprodukowana została całkowita liczba czterdziestu sześciu silników wielokrotnego użytku, z których do każego lotu były używane trzy<ref name=forum>KSC booklet, Quote: "Since the first Space Shuttle launch on April 12, 1981, 42 different SSMEs have successfully demonstrated the performance, safety, and reliability of the world's only reusable liquid-fuel rocket engine.", [http://www.collectspace.com/ubb/Forum30/HTML/000409.html source]</ref>. NASA planuje zachowanie od 14 do 16 silników w wersji Block II w celu potencjalnego ich wykorzystania w przyszłych, jeszcze niezdefiniowanych projektach<ref name=aw20110329/>. |

||

| Linia 52: | Linia 52: | ||

==Hydrogen fuel system== |

==Hydrogen fuel system== |

||

[[File:Orbiter main propulsion system.svg|right|300px|thumb|Orbiter main propulsion system]] |

[[File:Orbiter main propulsion system.svg|right|300px|thumb|Orbiter main propulsion system]] |

||

[[Fuel]] entered the orbiter at the liquid hydrogen feed line disconnect valve, then flowed into the orbiter liquid hydrogen feed line manifold and branches out into three parallel paths to each engine. In each liquid hydrogen branch, a prevalve permitted liquid hydrogen to flow to the low-pressure fuel turbopump when the prevalve was open. |

[[Paliwo|Fuel]] entered the orbiter at the liquid hydrogen feed line disconnect valve, then flowed into the orbiter liquid hydrogen feed line manifold and branches out into three parallel paths to each engine. In each liquid hydrogen branch, a prevalve permitted liquid hydrogen to flow to the low-pressure fuel turbopump when the prevalve was open. |

||

The low-pressure fuel turbopump (LPFTP) was an axial-flow pump driven by a two-stage turbine powered by gaseous hydrogen. It boosted the pressure of the liquid hydrogen from 30 to 276 psia (0.2 to 1.9 MPa) and supplies it to the high-pressure fuel turbopump (HPFTP). During engine operation, the pressure boost provided by the LPFTP permitted the HPFTP to operate at high speeds without cavitating. The LPFTP operated at approximately 16,185 [[rpm]]. The LPFTP was approximately {{convert|450|by|600|mm|in|abbr=on}}. It was connected to the vehicle propellant ducting and was supported in a fixed position by the orbiter structure 180 degrees from the LPOTP. |

The low-pressure fuel turbopump (LPFTP) was an axial-flow pump driven by a two-stage turbine powered by gaseous hydrogen. It boosted the pressure of the liquid hydrogen from 30 to 276 psia (0.2 to 1.9 MPa) and supplies it to the high-pressure fuel turbopump (HPFTP). During engine operation, the pressure boost provided by the LPFTP permitted the HPFTP to operate at high speeds without cavitating. The LPFTP operated at approximately 16,185 [[rpm]]. The LPFTP was approximately {{convert|450|by|600|mm|in|abbr=on}}. It was connected to the vehicle propellant ducting and was supported in a fixed position by the orbiter structure 180 degrees from the LPOTP. |

||

| Linia 60: | Linia 60: | ||

==Pre-burners and thrust control system== |

==Pre-burners and thrust control system== |

||

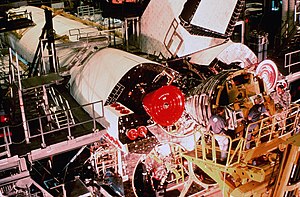

[[File:SSME2.jpg|left|300px|thumb|Main Engine #1 being installed into an orbiter in one of the Orbiter Processing Facilities (OPF)]] |

[[File:SSME2.jpg|left|300px|thumb|Main Engine #1 being installed into an orbiter in one of the Orbiter Processing Facilities (OPF)]] |

||

The oxidizer and fuel preburners were [[welded]] to the hot-[[ |

The oxidizer and fuel preburners were [[welded]] to the hot-[[Gaz|Gas]] [[manifold (general engineering)|manifold]]. The fuel and oxidizer entered the preburners and were mixed so that efficient combustion can occur. The augmented [[Łuk elektryczny|spark]] igniter was a small combination chamber located in the center of the injector of each preburner. The two dual-redundant spark igniters, which were activated by the engine controller, were used during the engine start sequence to initiate combustion in each preburner. They were turned off after approximately three seconds because the combustion process was then self-sustaining. The preburners produce the fuel-rich hot gas that passed through the turbines to generate the power to operate the high-pressure turbopumps. The oxidizer preburner's outflow drives a turbine that was connected to the HPOTP and the oxidizer preburner pump. The fuel preburner's outflow drives a turbine that was connected to the HPFTP. |

||

The speed of the HPOTP and HPFTP turbines depended on the position of the corresponding oxidizer and fuel preburner oxidizer valves. These valves were positioned by the engine controller, which used them to throttle the flow of liquid oxygen to the preburners and, thus, control engine thrust. The oxidizer and fuel preburner oxidizer valves increased or decreased the liquid oxygen flow, thus increasing or decreasing preburner chamber pressure, HPOTP and HPFTP turbine speed, and liquid oxygen and gaseous hydrogen flow into the main combustion chamber, which increased or decreased engine thrust, thus throttling the engine. The oxidizer and fuel preburner valves operated together to throttle the engine and maintain a constant 6-1 propellant mixture ratio. |

The speed of the HPOTP and HPFTP turbines depended on the position of the corresponding oxidizer and fuel preburner oxidizer valves. These valves were positioned by the engine controller, which used them to throttle the flow of liquid oxygen to the preburners and, thus, control engine thrust. The oxidizer and fuel preburner oxidizer valves increased or decreased the liquid oxygen flow, thus increasing or decreasing preburner chamber pressure, HPOTP and HPFTP turbine speed, and liquid oxygen and gaseous hydrogen flow into the main combustion chamber, which increased or decreased engine thrust, thus throttling the engine. The oxidizer and fuel preburner valves operated together to throttle the engine and maintain a constant 6-1 propellant mixture ratio. |

||

| Linia 67: | Linia 67: | ||

==Cooling control system== |

==Cooling control system== |

||

A [[ |

A [[Chłodziwo|Coolant]] control valve was mounted on the combustion chamber coolant bypass duct of each engine. The engine controller regulated the amount of gaseous hydrogen allowed to bypass the nozzle coolant loop, thus controlling its temperature. The chamber coolant valve was 100 % open before engine start. During engine operation, it was 100 % open for throttle settings of 100 to 109 % for maximum cooling. For throttle settings between 65 to 100 %, its position ranged from 66.4 to 100 % open for reduced cooling. |

||

[[File:In-flight close up of Space Shuttle Atlantis during launch (STS-117).jpg|thumb|right|250px|[[ |

[[File:In-flight close up of Space Shuttle Atlantis during launch (STS-117).jpg|thumb|right|250px|[[Atlantis (wahadłowiec)|Space Shuttle ''Atlantis''']] main engines visibly in operation during the launch of [[STS-117|STS-117]].]] |

||

==Combustion chamber and nozzle== |

==Combustion chamber and nozzle== |

||

| Linia 122: | Linia 122: | ||

===Pre-October 2010=== |

===Pre-October 2010=== |

||

At one point in the 2000s, the SSME was to see service in the post-Shuttle era as the main engines for the unmanned [[Ares V]] cargo-launch vehicle and as a second-stage engine for the manned-rated [[Ares I]] crew-launch vehicle. Although the use of the SSME seemed good on paper, as it would use current Shuttle technology after the Shuttle's retirement in 2010, it had several drawbacks: |

At one point in the 2000s, the SSME was to see service in the post-Shuttle era as the main engines for the unmanned [[Ares V|Ares V]] cargo-launch vehicle and as a second-stage engine for the manned-rated [[Ares I|Ares I]] crew-launch vehicle. Although the use of the SSME seemed good on paper, as it would use current Shuttle technology after the Shuttle's retirement in 2010, it had several drawbacks: |

||

* It would not be reusable, as they would be permanently attached to the discarded stage(s). |

* It would not be reusable, as they would be permanently attached to the discarded stage(s). |

||

* It would have to undergo a flight-readiness firing (FRF) before installation – the so-called "Main Engine Test" that NASA conducted with each new Orbiter and prior to the [[STS-26]] flight. |

* It would have to undergo a flight-readiness firing (FRF) before installation – the so-called "Main Engine Test" that NASA conducted with each new Orbiter and prior to the [[STS-26|STS-26]] flight. |

||

* It would be expensive, time-consuming, and weight-intensive to convert the ground-started SSME to an air-started version for the Ares I second stage. |

* It would be expensive, time-consuming, and weight-intensive to convert the ground-started SSME to an air-started version for the Ares I second stage. |

||

| Linia 191: | Linia 191: | ||

*SN-2005 5 |

*SN-2005 5 |

||

**[[STS-1]], [[STS-2]], [[STS-3]], [[STS-4]], [[STS-5]] |

**[[STS-1|STS-1]], [[STS-2|STS-2]], [[STS-3|STS-3]], [[STS-4|STS-4]], [[STS-5|STS-5]] |

||

*SN-2006 5 |

*SN-2006 5 |

||

**[[STS-1]], [[STS-2]], [[STS-3]], [[STS-4]], [[STS-5]] |

**[[STS-1|STS-1]], [[STS-2|STS-2]], [[STS-3|STS-3]], [[STS-4|STS-4]], [[STS-5|STS-5]] |

||

*SN-2007 5 |

*SN-2007 5 |

||

**[[STS-1]], [[STS-2]], [[STS-3]], [[STS-4]], [[STS-5]] |

**[[STS-1|STS-1]], [[STS-2|STS-2]], [[STS-3|STS-3]], [[STS-4|STS-4]], [[STS-5|STS-5]] |

||

*SN-2011 7 |

*SN-2011 7 |

||

**[[STS-9]], [[STS-51J]], [[STS-61B]], [[STS-33]], [[STS-31]], [[STS-41]], [[STS-50]] |

**[[STS-9|STS-9]], [[STS-51J]], [[STS-61B]], [[STS-33|STS-33]], [[STS-31|STS-31]], [[STS-41|STS-41]], [[STS-50|STS-50]] |

||

*SN-2012 22 |

*SN-2012 22 |

||

**[[STS-6]], [[STS-7]], [[STS-8]], [[STS-41B]], [[STS-41C]], [[STS-51A]], [[STS-51C]], [[STS-51D]], [[STS-51G]], [[STS-51I]], [[STS-35]], [[STS-43]], [[STS-45]], [[STS-53]], [[STS-60]], [[STS-67]], [[STS-74]], [[STS-79]], [[STS-83]], [[STS-86]], [[STS-90]], [[STS-93]] |

**[[STS-6|STS-6]], [[STS-7|STS-7]], [[STS-8|STS-8]], [[STS-41B]], [[STS-41C]], [[STS-51A]], [[STS-51C]], [[STS-51D]], [[STS-51G]], [[STS-51I]], [[STS-35|STS-35]], [[STS-43|STS-43]], [[STS-45|STS-45]], [[STS-53|STS-53]], [[STS-60|STS-60]], [[STS-67|STS-67]], [[STS-74|STS-74]], [[STS-79|STS-79]], [[STS-83|STS-83]], [[STS-86|STS-86]], [[STS-90|STS-90]], [[STS-93|STS-93]] |

||

*SN-2015 9 |

*SN-2015 9 |

||

**[[STS-6]], [[STS-7]], [[STS-8]], [[STS-41B]], [[STS-61C]], [[STS-40]], [[STS-44]], [[STS-49]], [[STS-52]] |

**[[STS-6|STS-6]], [[STS-7|STS-7]], [[STS-8|STS-8]], [[STS-41B]], [[STS-61C]], [[STS-40|STS-40]], [[STS-44|STS-44]], [[STS-49|STS-49]], [[STS-52|STS-52]] |

||

*SN-2017 14 |

*SN-2017 14 |

||

**[[STS-6]], [[STS-7]], [[STS-8]], [[STS-51J]], [[STS-61B]], [[STS-27]], [[STS-49]], [[STS-53]], [[STS-57]], [[STS-61]], [[STS-65]], [[STS-66]], [[STS-70]], [[STS-75]] |

**[[STS-6|STS-6]], [[STS-7|STS-7]], [[STS-8|STS-8]], [[STS-51J]], [[STS-61B]], [[STS-27|STS-27]], [[STS-49|STS-49]], [[STS-53|STS-53]], [[STS-57|STS-57]], [[STS-61|STS-61]], [[STS-65|STS-65]], [[STS-66|STS-66]], [[STS-70|STS-70]], [[STS-75|STS-75]] |

||

*SN-2018 12 |

*SN-2018 12 |

||

**[[STS-9]], [[STS-41D]], [[STS-51A]], [[STS-51C]], [[STS-51D]], [[STS-51G]], [[STS-51I]], [[STS-61C]], [[STS-54]], [[STS-56]], [[STS-58]], [[STS-59]] |

**[[STS-9|STS-9]], [[STS-41D]], [[STS-51A]], [[STS-51C]], [[STS-51D]], [[STS-51G]], [[STS-51I]], [[STS-61C]], [[STS-54|STS-54]], [[STS-56|STS-56]], [[STS-58|STS-58]], [[STS-59|STS-59]] |

||

*SN-2019 19 |

*SN-2019 19 |

||

**[[STS-9]], [[STS-51J]], [[STS-61B]], [[STS-26]], [[STS-28]], [[STS-36]], [[STS-38]], [[STS-37]], [[STS-48]], [[STS-50]], [[STS-54]], [[STS-57]], [[STS-61]], [[STS-65]], [[STS-70]], [[STS-76]], [[STS-83]], [[STS-86]], [[STS-93]] |

**[[STS-9|STS-9]], [[STS-51J]], [[STS-61B]], [[STS-26|STS-26]], [[STS-28|STS-28]], [[STS-36|STS-36]], [[STS-38|STS-38]], [[STS-37|STS-37]], [[STS-48|STS-48]], [[STS-50|STS-50]], [[STS-54|STS-54]], [[STS-57|STS-57]], [[STS-61|STS-61]], [[STS-65|STS-65]], [[STS-70|STS-70]], [[STS-76|STS-76]], [[STS-83|STS-83]], [[STS-86|STS-86]], [[STS-93|STS-93]] |

||

*SN-2020 6 |

*SN-2020 6 |

||

**[[STS-41C]], [[STS-41G]], [[STS-51B]], [[STS-51F]], [[STS-61A]], [[STS-51L]] |

**[[STS-41C]], [[STS-41G]], [[STS-51B]], [[STS-51F]], [[STS-61A]], [[STS-51L]] |

||

| Linia 213: | Linia 213: | ||

**[[STS-41D]], [[STS-41G]], [[STS-51B]], [[STS-51F]], [[STS-61A]], [[STS-51L]] |

**[[STS-41D]], [[STS-41G]], [[STS-51B]], [[STS-51F]], [[STS-61A]], [[STS-51L]] |

||

*SN-2022 8 |

*SN-2022 8 |

||

**[[STS-26]], [[STS-29]], [[STS-28]], [[STS-32]], [[STS-38]], [[STS-40]], [[STS-42]], [[STS-47]] |

**[[STS-26|STS-26]], [[STS-29|STS-29]], [[STS-28|STS-28]], [[STS-32|STS-32]], [[STS-38|STS-38]], [[STS-40|STS-40]], [[STS-42|STS-42]], [[STS-47|STS-47]] |

||

*SN-2023 5 |

*SN-2023 5 |

||

**[[STS-41G]], [[STS-51B]], [[STS-51F]], [[STS-61A]], [[STS-51L]] |

**[[STS-41G]], [[STS-51B]], [[STS-51F]], [[STS-61A]], [[STS-51L]] |

||

*SN-2024 7 |

*SN-2024 7 |

||

**[[STS-32]], [[STS-35]], [[STS-43]], [[STS-45]], [[STS-53]], [[STS-56]], [[STS-58]] |

**[[STS-32|STS-32]], [[STS-35|STS-35]], [[STS-43|STS-43]], [[STS-45|STS-45]], [[STS-53|STS-53]], [[STS-56|STS-56]], [[STS-58|STS-58]] |

||

*SN-2026 6 |

*SN-2026 6 |

||

**[[STS-39]], [[STS-42]], [[STS-47]], [[STS-68]], [[STS-74]], [[STS-80]] |

**[[STS-39|STS-39]], [[STS-42|STS-42]], [[STS-47|STS-47]], [[STS-68|STS-68]], [[STS-74|STS-74]], [[STS-80|STS-80]] |

||

*SN-2027 7 |

*SN-2027 7 |

||

**[[STS-30]], [[STS-34]], [[STS-36]], [[STS-38]], [[STS-40]], [[STS-42]], [[STS-46]] |

**[[STS-30|STS-30]], [[STS-34|STS-34]], [[STS-36|STS-36]], [[STS-38|STS-38]], [[STS-40|STS-40]], [[STS-42|STS-42]], [[STS-46|STS-46]] |

||

*SN-2028 11 |

*SN-2028 11 |

||

**[[STS-26]], [[STS-29]], [[STS-28]], [[STS-32]], [[STS-35]], [[STS-43]], [[STS-45]], [[STS-59]], [[STS-68]], [[STS-71]], [[STS-72]] |

**[[STS-26|STS-26]], [[STS-29|STS-29]], [[STS-28|STS-28]], [[STS-32|STS-32]], [[STS-35|STS-35]], [[STS-43|STS-43]], [[STS-45|STS-45]], [[STS-59|STS-59]], [[STS-68|STS-68]], [[STS-71|STS-71]], [[STS-72|STS-72]] |

||

*SN-2029 15 |

*SN-2029 15 |

||

**[[STS-27]], [[STS-30]], [[STS-34]], [[STS-39]], [[STS-44]], [[STS-47]], [[STS-55]], [[STS-51]], [[STS-62]], [[STS-64]], [[STS-63]], [[STS-69]], [[STS-75]], [[STS-80]], [[STS-84]] |

**[[STS-27|STS-27]], [[STS-30|STS-30]], [[STS-34|STS-34]], [[STS-39|STS-39]], [[STS-44|STS-44]], [[STS-47|STS-47]], [[STS-55|STS-55]], [[STS-51|STS-51]], [[STS-62|STS-62]], [[STS-64|STS-64]], [[STS-63|STS-63]], [[STS-69|STS-69]], [[STS-75|STS-75]], [[STS-80|STS-80]], [[STS-84|STS-84]] |

||

*SN-2030 10 |

*SN-2030 10 |

||

**[[STS-27]], [[STS-30]], [[STS-34]], [[STS-36]], [[STS-39]], [[STS-44]], [[STS-49]], [[STS-52]], [[STS-65]], [[STS-66]] |

**[[STS-27|STS-27]], [[STS-30|STS-30]], [[STS-34|STS-34]], [[STS-36|STS-36]], [[STS-39|STS-39]], [[STS-44|STS-44]], [[STS-49|STS-49]], [[STS-52|STS-52]], [[STS-65|STS-65]], [[STS-66|STS-66]] |

||

*SN-2031 17 |

*SN-2031 17 |

||

**[[STS-29]], [[STS-33]], [[STS-31]], [[STS-41]], [[STS-37]], [[STS-48]], [[STS-50]], [[STS-55]], [[STS-51]], [[STS-62]], [[STS-64]], [[STS-67]], [[STS-73]], [[STS-79]], [[STS-84]], [[STS-87]], [[STS-93]] |

**[[STS-29|STS-29]], [[STS-33|STS-33]], [[STS-31|STS-31]], [[STS-41|STS-41]], [[STS-37|STS-37]], [[STS-48|STS-48]], [[STS-50|STS-50]], [[STS-55|STS-55]], [[STS-51|STS-51]], [[STS-62|STS-62]], [[STS-64|STS-64]], [[STS-67|STS-67]], [[STS-73|STS-73]], [[STS-79|STS-79]], [[STS-84|STS-84]], [[STS-87|STS-87]], [[STS-93|STS-93]] |

||

*SN-2032 7 |

*SN-2032 7 |

||

**[[STS-46]], [[STS-60]], [[STS-71]], [[STS-74]], [[STS-80]], [[STS-84]], [[STS-90]] |

**[[STS-46|STS-46]], [[STS-60|STS-60]], [[STS-71|STS-71]], [[STS-74|STS-74]], [[STS-80|STS-80]], [[STS-84|STS-84]], [[STS-90|STS-90]] |

||

*SN-2033 9 |

*SN-2033 9 |

||

**[[STS-46]], [[STS-54]], [[STS-56]], [[STS-61]], [[STS-59]], [[STS-68]], [[STS-67]], [[STS-79]], [[STS-94]] |

**[[STS-46|STS-46]], [[STS-54|STS-54]], [[STS-56|STS-56]], [[STS-61|STS-61]], [[STS-59|STS-59]], [[STS-68|STS-68]], [[STS-67|STS-67]], [[STS-79|STS-79]], [[STS-94|STS-94]] |

||

*SN-2034 9 |

*SN-2034 9 |

||

**[[STS-52]], [[STS-57]], [[STS-51]], [[STS-60]], [[STS-66]], [[STS-71]], [[STS-75]], [[STS-81]], [[STS-94]] |

**[[STS-52|STS-52]], [[STS-57|STS-57]], [[STS-51|STS-51]], [[STS-60|STS-60]], [[STS-66|STS-66]], [[STS-71|STS-71]], [[STS-75|STS-75]], [[STS-81|STS-81]], [[STS-94|STS-94]] |

||

*SN-2035 3 |

*SN-2035 3 |

||

**[[STS-63]], [[STS-69]], [[STS-76]] |

**[[STS-63|STS-63]], [[STS-69|STS-69]], [[STS-76|STS-76]] |

||

*SN-2036 3 |

*SN-2036 3 |

||

**[[STS-70]], [[STS-72]], [[STS-78]] |

**[[STS-70|STS-70]], [[STS-72|STS-72]], [[STS-78|STS-78]] |

||

*SN-2037 5 |

*SN-2037 5 |

||

**[[STS-73]], [[STS-77]], [[STS-82]], [[STS-94]], [[STS-87]] |

**[[STS-73|STS-73]], [[STS-77|STS-77]], [[STS-82|STS-82]], [[STS-94|STS-94]], [[STS-87|STS-87]] |

||

*SN-2038 3 |

*SN-2038 3 |

||

**[[STS-73]], [[STS-77]], [[STS-82]] |

**[[STS-73|STS-73]], [[STS-77|STS-77]], [[STS-82|STS-82]] |

||

*SN-2039 4 |

*SN-2039 4 |

||

**[[STS-72]], [[STS-78]], [[STS-85]], [[STS-87]] |

**[[STS-72|STS-72]], [[STS-78|STS-78]], [[STS-85|STS-85]], [[STS-87|STS-87]] |

||

*SN-2040 4 |

*SN-2040 4 |

||

**[[STS-77]], [[STS-82]], [[STS-86]], [[STS-91]] |

**[[STS-77|STS-77]], [[STS-82|STS-82]], [[STS-86|STS-86]], [[STS-91|STS-91]] |

||

*SN-2041 5 |

*SN-2041 5 |

||

**[[STS-78]], [[STS-81]], [[STS-85]], [[STS-90]], [[STS-88]] |

**[[STS-78|STS-78]], [[STS-81|STS-81]], [[STS-85|STS-85]], [[STS-90|STS-90]], [[STS-88|STS-88]] |

||

*SN-2042 3 |

*SN-2042 3 |

||

**[[STS-81]], [[STS-85]], [[STS-91]] |

**[[STS-81|STS-81]], [[STS-85|STS-85]], [[STS-91|STS-91]] |

||

*SN-2043 7 |

*SN-2043 7 |

||

**[[STS-89]], [[STS-95]], [[STS-103]], [[STS-101]], [[STS-97]], [[STS-100]], [[STS-108]] |

**[[STS-89|STS-89]], [[STS-95|STS-95]], [[STS-103|STS-103]], [[STS-101|STS-101]], [[STS-97|STS-97]], [[STS-100|STS-100]], [[STS-108|STS-108]] |

||

*SN-2044 7 |

*SN-2044 7 |

||

**[[STS-89]], [[STS-88]], [[STS-99]], [[STS-106]], [[STS-98]], [[STS-105]], [[STS-111]] |

**[[STS-89|STS-89]], [[STS-88|STS-88]], [[STS-99|STS-99]], [[STS-106|STS-106]], [[STS-98|STS-98]], [[STS-105|STS-105]], [[STS-111|STS-111]] |

||

*SN-2045 8 |

*SN-2045 8 |

||

**[[STS-89]], [[STS-95]], [[STS-92]], [[STS-102]], [[STS-105]], [[STS-110]], [[STS-113]], [[STS-121]] |

**[[STS-89|STS-89]], [[STS-95|STS-95]], [[STS-92|STS-92]], [[STS-102|STS-102]], [[STS-105|STS-105]], [[STS-110|STS-110]], [[STS-113|STS-113]], [[STS-121|STS-121]] |

||

*SN-2047 6 |

*SN-2047 6 |

||

**[[STS-91]], [[STS-96]], [[STS-106]], [[STS-98]], [[STS-104]], [[STS-109]] |

**[[STS-91|STS-91]], [[STS-96|STS-96]], [[STS-106|STS-106]], [[STS-98|STS-98]], [[STS-104|STS-104]], [[STS-109|STS-109]] |

||

*SN-2048 4 |

*SN-2048 4 |

||

**[[STS-95]], [[STS-92]], [[STS-110]], [[STS-112]] |

**[[STS-95|STS-95]], [[STS-92|STS-92]], [[STS-110|STS-110]], [[STS-112|STS-112]] |

||

*SN-2049 7 |

*SN-2049 7 |

||

**[[STS-96]], [[STS-103]], [[STS-101]], [[STS-97]], [[STS-100]], [[STS-108]], [[STS-107]] |

**[[STS-96|STS-96]], [[STS-103|STS-103]], [[STS-101|STS-101]], [[STS-97|STS-97]], [[STS-100|STS-100]], [[STS-108|STS-108]], [[STS-107|STS-107]] |

||

*SN-2050 5 |

*SN-2050 5 |

||

**[[STS-88]], [[STS-99]], [[STS-108]], [[STS-111]], [[STS-113]] |

**[[STS-88|STS-88]], [[STS-99|STS-99]], [[STS-108|STS-108]], [[STS-111|STS-111]], [[STS-113|STS-113]] |

||

*SN-2051 4 |

*SN-2051 4 |

||

**[[STS-96]], [[STS-104]], [[STS-110]], [[STS-112]] |

**[[STS-96|STS-96]], [[STS-104|STS-104]], [[STS-110|STS-110]], [[STS-112|STS-112]] |

||

*SN-2052 5 |

*SN-2052 5 |

||

**[[STS-99]], [[STS-106]], [[STS-98]], [[STS-105]], [[STS-121]] |

**[[STS-99|STS-99]], [[STS-106|STS-106]], [[STS-98|STS-98]], [[STS-105|STS-105]], [[STS-121|STS-121]] |

||

*SN-2053 5 |

*SN-2053 5 |

||

**[[STS-103]], [[STS-92]], [[STS-102]], [[STS-109]], [[STS-107]] |

**[[STS-103|STS-103]], [[STS-92|STS-92]], [[STS-102|STS-102]], [[STS-109|STS-109]], [[STS-107|STS-107]] |

||

*SN-2054 6 |

*SN-2054 6 |

||

**[[STS-101]], [[STS-97]], [[STS-100]], [[STS-111]], [[STS-114]], [[STS-121]] |

**[[STS-101|STS-101]], [[STS-97|STS-97]], [[STS-100|STS-100]], [[STS-111|STS-111]], [[STS-114|STS-114]], [[STS-121|STS-121]] |

||

*SN-2055 1 |

*SN-2055 1 |

||

**[[STS-112]] |

**[[STS-112|STS-112]] |

||

*SN-2056 6 |

*SN-2056 6 |

||

**[[STS-102]], [[STS-104]], [[STS-109]], [[STS-113]], [[STS-107]], [[STS-114]] |

**[[STS-102|STS-102]], [[STS-104|STS-104]], [[STS-109|STS-109]], [[STS-113|STS-113]], [[STS-107|STS-107]], [[STS-114|STS-114]] |

||

*SN-2057 1 |

*SN-2057 1 |

||

**[[STS-114]] |

**[[STS-114|STS-114]] |

||

*SN-2107 5 |

*SN-2107 5 |

||

**[[STS-33]], [[STS-31]], [[STS-41]], [[STS-37]], [[STS-48]] |

**[[STS-33|STS-33]], [[STS-31|STS-31]], [[STS-41|STS-41]], [[STS-37|STS-37]], [[STS-48|STS-48]] |

||

*SN-2109 17 |

*SN-2109 17 |

||

**[[STS-41B]], [[STS-41C]], [[STS-41D]], [[STS-51A]], [[STS-51C]], [[STS-51D]], [[STS-51G]], [[STS-51I]], [[STS-61C]], [[STS-55]], [[STS-58]], [[STS-62]], [[STS-64]], [[STS-63]], [[STS-69]], [[STS-76]], [[STS-83]] |

**[[STS-41B]], [[STS-41C]], [[STS-41D]], [[STS-51A]], [[STS-51C]], [[STS-51D]], [[STS-51G]], [[STS-51I]], [[STS-61C]], [[STS-55|STS-55]], [[STS-58|STS-58]], [[STS-62|STS-62]], [[STS-64|STS-64]], [[STS-63|STS-63]], [[STS-69|STS-69]], [[STS-76|STS-76]], [[STS-83|STS-83]] |

||

== Zobacz też == |

== Zobacz też == |

||

* [[MPTA-098]] - przedmiot testów używany w czasie prac rozwojowym nad STS |

* [[MPTA-098]] - przedmiot testów używany w czasie prac rozwojowym nad STS |

||

* [[Rakieta dodatkowa na paliwo stałe]] - używana w czasie wynoszenia dla uzyskania dodatkowej mocy |

* [[Rakieta dodatkowa na paliwo stałe]] - używana w czasie wynoszenia dla uzyskania dodatkowej mocy |

||

* [[RD-0120]] - analogiczny silnik rakietowy stosowany w systemie startowym [[Energia]] |

* [[RD-0120]] - analogiczny silnik rakietowy stosowany w systemie startowym [[Energia (rakieta)|Energia]] |

||

== Źródła == |

== Źródła == |

||

* {{Cytuj stronę | url = http://www.shuttlepresskit.com/scom/216.pdf | tytuł = NASA Shuttle Press Kit SSME Reference | format = PDF}} |

* {{Cytuj stronę | url = http://www.shuttlepresskit.com/scom/216.pdf | tytuł = NASA Shuttle Press Kit SSME Reference | format = PDF}} |

||

* {{Cytuj stronę | url = http://www.boeing.com/defense-space/space/returntoflight/vehicleupgrades/ssme.html | tytuł = Space Shuttle Main Engine | publisher = [[Boeing]]}} |

* {{Cytuj stronę | url = http://www.boeing.com/defense-space/space/returntoflight/vehicleupgrades/ssme.html | tytuł = Space Shuttle Main Engine | publisher = [[Boeing]]}} |

||

* {{Cytuj stronę | url = http://www.nasa.gov/centers/marshall/news/background/facts/ssme.html | tytuł = Space Shuttle Main Engine Enhancements | publisher = [[NASA]]}} |

* {{Cytuj stronę | url = http://www.nasa.gov/centers/marshall/news/background/facts/ssme.html | tytuł = Space Shuttle Main Engine Enhancements | publisher = [[NASA|NASA]]}} |

||

* {{Cytuj stronę | url = http://science.nasa.gov/headlines/y2002/06nov_ssme.htm | tytuł = The Roar of Innovation | publisher = [[NASA]]}} |

* {{Cytuj stronę | url = http://science.nasa.gov/headlines/y2002/06nov_ssme.htm | tytuł = The Roar of Innovation | publisher = [[NASA|NASA]]}} |

||

* {{Cytuj stronę | url = http://users.ipfw.edu/modesitk/shuttleEngine.htm | tytuł = Space Shuttle Main Engine - incredible facts}} |

* {{Cytuj stronę | url = http://users.ipfw.edu/modesitk/shuttleEngine.htm | tytuł = Space Shuttle Main Engine - incredible facts}} |

||

* {{Cytuj stronę | url = http://www.enginehistory.org/SSME/SSME1.pdf#search='cutaway%20view%20space%20shuttle%20main%20engine | tytuł = Space Shuttle Main Engine The First Ten Years | format = PDF}} |

* {{Cytuj stronę | url = http://www.enginehistory.org/SSME/SSME1.pdf#search='cutaway%20view%20space%20shuttle%20main%20engine | tytuł = Space Shuttle Main Engine The First Ten Years | format = PDF}} |

||

Wersja z 11:06, 18 sie 2011

| Państwo |

{{{państwo}}} |

|---|---|

| Osiągi | |

| Parametry | |

| Wymiary | |

| Długość |

4,24 |

| Średnica |

1,63 |

| Masa |

3 177 |

Główne silniki promu kosmicznego (ang. Space Shuttle Main Engines - SSME) to trzy silniki wielokrotnego użytku orbitera promu kosmicznego. Każde wyniesienie zespołu wahadłowca jest wspomagane przez trzy z zasobu czternastu silników stosowanych przez NASA w systemie transportu kosmicznego[1]. Po każdym locie silniki były demontowane z orbitera, poddawane inspekcji i odnawianiu w celu przygotowania do kolejnego lotu. Silnik posiada także przemysłowe oznaczenie RS-24 lub RS-25.

W ramach programu Space Transportation System wyprodukowana została całkowita liczba czterdziestu sześciu silników wielokrotnego użytku, z których do każego lotu były używane trzy[2]. NASA planuje zachowanie od 14 do 16 silników w wersji Block II w celu potencjalnego ich wykorzystania w przyszłych, jeszcze niezdefiniowanych projektach[3].

Wstęp

Główne silniki promu kosmicznego spalały ciekły wodór i ciekły tlen ze zbiornika zewnętrznego promu (ET). Używane są jako napęd w czasie wznoszenia, uzupełniając dwie rakiety dodatkowe na paliwo stałe (SRB) o większej mocy. Czasem SSME używane są także przy manewrach orbitalnych. Każdy z głównych silników generuje prawie 1.8 MN ciągu w momencie wyniesienia (oderwania się promu od ziemi w momencie startu). Silniki są zdolne do wygenerowania impulsu właściwego (Iwł) długości 453 sekund w próźni lub 363 sekund na poziomie morza (prędkości wylotowe odpowiednio 4 440 m/s i 3 560 m/s). Ogólnie, główny silnik promu kosmicznego waży około 3,2 t. Silniki są wymontowywane po każdym locie i transportowane do ośrodka przetwarzania silników (ang. Space Shuttle Main Engine Processing Facility - SSMEPF) w celu dokonania sprawdzenia i wymian komponentów, które tego wymagają.

Silniki rakietowe promu kosmicznego są zdolne do pracy w ekstremalnych temperaturach. Ciekły wodór jest przechowywany w temperaturze -253 °C. Jednakże kiedy jest on spalany wraz z ciekłym tlenem, temperatura w komorze spalania osiąga do 3 300 °C, więcej niż temperatura wrzenia żelaza.

Poza trzema głównymi silnikami, orbiter posiada 44 mniejsze rakiety na swoim pokładzie, będące częścią systemu manewrowania orbitalnego (OMS) i systemu kontroli reakcji (RCS). Systemy te pozwalają na sterowanie, zmianę pozycji w przestrzeni (obroty) i zmianę wysokości promu w czasie pozostawania na orbicie.

W czasie pracy silnika, paliwo i utleniacz ze zbiornika zewnętrznego pompowane jest na pokład orbitera poprzez złącze, a dalej do głównych linii przesyłowych systemu napędowego orbitera. Tam paliwo i utleniacz rozgałęziają się na trzy równoległe linie, do każdego z silników. Każde rozgałęzienie posiada osobny zawór, zabezpieczający przed swobodnym wpływaniem paliwa lub utleniacza do odpowidniej turbopompy.

System utleniacza

Niskociśnieniowa turbopompa utleniacza (ang. The Low Pressure Oxidizer Turbopump - LPOTP) to pompa śmigłowa napędzana przez sześciostopniową turbinę zasilaną przez ciekły tlen. Zwiększa ona ciśnienie ciekłego tlenu z 0,7 do 2.9 MPa. Przepływ z LPOTP jest kierowany do wysokociśnieniowej turbopompy utleniacza (ang. High-Pressure Oxidizer Turbopump - HPOTP). W czasie działania silnika, zwiększenie ciśnienia pozwala pompie wysokociśnieniowej na pracę z dużą prędkością bez kawitacji. Pompa niskociśnieniowa działa z prędkością około 5 150 obrotów na minutę. Pompa ta, o wymiarach ok. 450 na 450 mm, jest połączona z instalacją przesyłu paliwa i miejsce jej zamocowania jest dodatkowo chronione przez strukturę orbitera.

Pompa wysokociśnieniowa składa się z dwóch jednostopniowych pomp odśrodkowych (pompa główna i pompa przedspalania) zamocowanych na wspólnym wale i zasilanych przez dwustopniową turbinę gazową.

Główna pompa podwyższa ciśnienie ciekłego tlenu z 2,9 do 30 MPa pracując przy średnio 28 120 rpm (obrotach na minutę). Strumień wychodzący z HPOTP jest dzielony na kilka ścieżek, z których jedna jest kierowana do zasilania turbiny LPOTP. Inna ścieżka kierowana jest poprzez główny zawór utleniacza do komory spalania. Kolejny mały strumień jest redukowany i wprowadzany do wymiennika ciepła utleniacza. Ciekły tlen wpływa przez zawór przeciwzalewowy, który blokuje dostęp do wymiennika ciepła, jeśli nie jest on wystarczająco ciepły aby zamienić tlen w gaz. Wymiennik ciepła wykorzystuje ciepło zawarte w gazach wylotowych turbiny HPOTP. Gaz jest kierowany do kolektora a później do zbiornika zewnętrznego, aby utrzymać ciśnienie w zbiorniku ciekłego tlenu. Kolejny strumień wpływa do pompy przedspalającej drugiego stopnia HPOT, przez co ciśnienie ciekłego tlenu zwiększane jest z 30 do 51 MPa. Przepływa przez komorę wstępnego spalania utleniacza i dalej do komory wstępnego spalania paliwa.

HPOTP ma wymiary około 60×90 cm. Jest zamocowana przez kołnierze do kolektora gorących gazów. Turbina HPOTP i pompy HPOTP są zamontowane na wspólnym wale.

Mieszanie bogatego w paliwo gorącego gazu w sekcji turbinowej i ciekłego tlenu w głównej pompie mogło stwarzać zagrożenie eksplozją. Aby temu zapobiec, te dwie sekcje są odseparowane wnęką, która w czasie pracy silnika jest stale przeczyszczana przez wodór z zasobnika głównego systemu napędowego. Dwie plomby minimalizują wycieki do wnęki. Jedna plomba mieści się między sekcją turbiny a wnęką, druga między sekcją pompy a wnęką. Utrata ciśnienia wodoru we wnęce powoduje automatyczne wyłączenie silnika.

Hydrogen fuel system

Fuel entered the orbiter at the liquid hydrogen feed line disconnect valve, then flowed into the orbiter liquid hydrogen feed line manifold and branches out into three parallel paths to each engine. In each liquid hydrogen branch, a prevalve permitted liquid hydrogen to flow to the low-pressure fuel turbopump when the prevalve was open.

The low-pressure fuel turbopump (LPFTP) was an axial-flow pump driven by a two-stage turbine powered by gaseous hydrogen. It boosted the pressure of the liquid hydrogen from 30 to 276 psia (0.2 to 1.9 MPa) and supplies it to the high-pressure fuel turbopump (HPFTP). During engine operation, the pressure boost provided by the LPFTP permitted the HPFTP to operate at high speeds without cavitating. The LPFTP operated at approximately 16,185 rpm. The LPFTP was approximately 450 na 600 mm (18 na 24 in). It was connected to the vehicle propellant ducting and was supported in a fixed position by the orbiter structure 180 degrees from the LPOTP.

The HPFTP was a three-stage centrifugal pump driven by a two-stage, hot-gas turbine. It boosted the pressure of the liquid hydrogen from 1.9 to 45 MPa (276 to 6,515 psia). The HPFTP operated at approximately 35,360 rpm. The discharge flow from the turbopump was routed to and through the main valve and then split into three flow paths. One path was through the jacket of the main combustion chamber, where the hydrogen ws used to cool the chamber walls. It was then routed from the main combustion chamber to the LPFTP, where it was used to drive the LPFTP turbine. A small portion of the flow from the LPFTP was then directed to a common manifold from all three engines to form a single path to the external tank to maintain liquid hydrogen tank pressurization. The remaining hydrogen passes between the inner and outer walls to cool the hot-gas manifold and was discharged into the main combustion chamber. The second hydrogen flow path from the main fuel valve was through the engine nozzle (to cool the nozzle). It then joined the third flow path from the chamber coolant valve. The combined flow was then directed to the fuel and oxidizer preburners. The HPFTP was approximately 550 na 1 100 mm (22 na 43 in). It was attached by flanges to the hot-gas manifold.

Pre-burners and thrust control system

The oxidizer and fuel preburners were welded to the hot-Gas manifold. The fuel and oxidizer entered the preburners and were mixed so that efficient combustion can occur. The augmented spark igniter was a small combination chamber located in the center of the injector of each preburner. The two dual-redundant spark igniters, which were activated by the engine controller, were used during the engine start sequence to initiate combustion in each preburner. They were turned off after approximately three seconds because the combustion process was then self-sustaining. The preburners produce the fuel-rich hot gas that passed through the turbines to generate the power to operate the high-pressure turbopumps. The oxidizer preburner's outflow drives a turbine that was connected to the HPOTP and the oxidizer preburner pump. The fuel preburner's outflow drives a turbine that was connected to the HPFTP.

The speed of the HPOTP and HPFTP turbines depended on the position of the corresponding oxidizer and fuel preburner oxidizer valves. These valves were positioned by the engine controller, which used them to throttle the flow of liquid oxygen to the preburners and, thus, control engine thrust. The oxidizer and fuel preburner oxidizer valves increased or decreased the liquid oxygen flow, thus increasing or decreasing preburner chamber pressure, HPOTP and HPFTP turbine speed, and liquid oxygen and gaseous hydrogen flow into the main combustion chamber, which increased or decreased engine thrust, thus throttling the engine. The oxidizer and fuel preburner valves operated together to throttle the engine and maintain a constant 6-1 propellant mixture ratio.

The main oxidizer valve and the main fuel valve control the flow of liquid oxygen and liquid hydrogen into the engine and were controlled by each engine controller. When an engine was operating, the main valves were fully open.

Cooling control system

A Coolant control valve was mounted on the combustion chamber coolant bypass duct of each engine. The engine controller regulated the amount of gaseous hydrogen allowed to bypass the nozzle coolant loop, thus controlling its temperature. The chamber coolant valve was 100 % open before engine start. During engine operation, it was 100 % open for throttle settings of 100 to 109 % for maximum cooling. For throttle settings between 65 to 100 %, its position ranged from 66.4 to 100 % open for reduced cooling.

Combustion chamber and nozzle

Each engine main combustion chamber received fuel-rich hot gas from a hot-gas manifold cooling circuit. The gaseous hydrogen and liquid oxygen enter the chamber at the injector, which mixed the propellants. A small augmented spark igniter chamber was located in the center of the injector. The dual-redundant igniter was used during the engine start sequence to initiate combustion. The igniters were turned off after approximately three seconds because the combustion process was self-sustaining. The main injector and dome assembly was welded to the hot-gas manifold. The main combustion chamber also was bolted to the hot-gas manifold.

The inner surface of each combustion chamber, as well as the inner surface of each nozzle, was cooled by liquid hydrogen flowing through brazed stainless steel tube-wall coolant passages. The nozzle assembly was a bell-shaped extension bolted to the main combustion chamber. The nozzle was 2,9 m (110 in) long, and the outside diameter of the exit was 2,4 m (94 in). A support ring welded to the forward end of the nozzle was the engine attach point to the orbiter-supplied heat shield. Thermal protection was necessary because of the exposure portions of the nozzles experience during the launch, ascent, on-orbit and entry phases of a mission. The insulation consists of four layers of metallic batting covered with a metallic foil and screening.

For a nozzle able to run at sea level, the SSME nozzle had an unusually large expansion ratio (about 77) for the chamber pressure. A nozzle that large would normally undergo flow separation of the jet from the nozzle which would cause control difficulties and could even mechanically damage the vehicle. Instead the Rocketdyne engineers varied the angle of the nozzle, reducing it near the exit. This raised the pressure just around the rim to between 4,6 i 5,7 psi (32 i 39 kPa), and prevents flow separation. The inner part of the flow was at much lower pressure, around 2 psi (14 kPa) or less.[4]

Main valves

The five propellant valves on each engine (oxidizer preburner oxidizer, fuel preburner oxidizer, main oxidizer, main fuel, and chamber coolant) were hydraulically actuated and controlled by electrical signals from the engine controller. They can be fully closed by using the MPS engine helium supply system as a backup actuation system.

The main oxidizer valve and fuel bleed valve were used after shutdown. The main oxidizer valve was opened during a propellant dump to allow residual liquid oxygen to be dumped overboard through the engine, and the fuel bleed valve was opened to allow residual liquid hydrogen to be dumped through the liquid hydrogen fill and drain valves overboard. After the dump was completed, the valves close and remain closed for the remainder of the mission.

Gimbal

The gimbal bearing was bolted to the main injector and dome assembly and was the thrust interface between the engine and orbiter. The bearing assembly was approximately 290 na 360 mm (11 na 14 in).

The low-pressure oxygen and low-pressure fuel turbopumps were mounted 180 degrees apart on the orbiter's aft fuselage thrust structure. The lines from the low-pressure turbopumps to the high-pressure turbopumps contain flexible bellows that enable the low-pressure turbopumps to remain stationary while the rest of the engine was gimbaled for thrust vector control. The liquid hydrogen line from the LPFTP to the HPFTP was insulated to prevent the formation of liquid air.

Controller

An important innovation was the inclusion of an integrated controller in the engine itself: the SSME controller. This digital computer (originally composed of two redundant Honeywell HDC-601 computers,[5] and later replaced with a system with two double-redundant Motorola 68000 processors[6] for a total of 4 M68000s per controller) had two tasks: control the engine's burning process, and check itself. This arrangement greatly simplified the wiring between the engine and the shuttle, because all the sensors and actuators were connected directly to only the controller. Using a dedicated system also simplified the software and improved its reliability.

Two independent, dual-CPU computers, A and B, form the controller, giving redundancy to the system. The failure of controller system A will automatically switch to controller system B without impeding operational capabilities; the subsequent failure of controller system B will provide a graceful shutdown of the engine.

Within each system (A and B), the two M68000s operate in "lock-step", thereby enabling each system to detect failures by comparing the TTL signal levels of the buses of the two M68000 processors within that system. If differences were encountered between the two buses, then an interrupt was generated and control turned over to the other system. Because of subtle differences M68000s from Motorola and the second source manufacturer TRW, each system uses M68000s from the same manufacturer. (i.e. System A would have two Motorola CPUs while System B would have two CPUs manufactured by TRW.)

Memory for both Block I and Block II Main Engine Controllers were of the "plated-wire" type. Plated-wire memory functions in a manner similar to magnetic core memory and retains data even after power was turned off. (In the investigation of the Challenger accident, the MECs that were recovered from the seafloor were delivered to Honeywell for examination and analysis. Despite having been immersed in salt water for some time, after cleanup and some minor repairs, it was determined that the memory data was intact and Honeywell technicians were able to extract the memory contents for forensic examination.)

Thrust specifications

SSME thrust (or power level) can be throttled between 67 to 109% of rated thrust. Current launches use 104.5%, with 106 or 109% available for abort contingencies. Thrust can be specified as sea level or vacuum thrust. Vacuum thrust will be higher due to the absence of atmospheric effects.

| Sea level | Vacuum | |

|---|---|---|

| 100% thrust | 1 670 kN (380 000 lbf) | 2 090 kN (470 000 lbf) |

| 104.5% thrust | 1 750 kN (390 000 lbf) | 2 170 kN (490 000 lbf) |

| 109% thrust | 1 860 kN (420 000 lbf) | 2 280 kN (510 000 lbf) |

Specifying power levels over 100% may seem nonsensical, but there was a logic behind it. The 100% level does not mean the maximum physical power level attainable. Rather it was a specification, decided on early during SSME development, for the expected rated power level. Later studies indicated the engine could operate safely at levels above 100%, which was now the norm. Maintaining the original relationship of power level to physical thrust helps reduce confusion. It created an unvarying fixed relationship, so that test data, or operational data from past or future missions can be easily compared. If each time the power level was increased, that value was made 100%, then all previous data and documentation would either require changing, or cross-checking against what physical thrust corresponded to 100% power level on that date.

SSME power level affects engine reliability. Studies indicate the probability of an engine failure increased rapidly with power levels over 104.5%, which was why those were retained for contingency use only.[7]

After Shuttle

During the period preceding final Space Shuttle retirement various plans for the several dozen engines were proposed, ranging from them all kept by NASA, to them all being given away.[8] For example, around 2008, NASA tried selling them for $400,000—800,000 each.[8] By early 2010, NASA planned to give them away for free.[8]

Pre-October 2010

At one point in the 2000s, the SSME was to see service in the post-Shuttle era as the main engines for the unmanned Ares V cargo-launch vehicle and as a second-stage engine for the manned-rated Ares I crew-launch vehicle. Although the use of the SSME seemed good on paper, as it would use current Shuttle technology after the Shuttle's retirement in 2010, it had several drawbacks:

- It would not be reusable, as they would be permanently attached to the discarded stage(s).

- It would have to undergo a flight-readiness firing (FRF) before installation – the so-called "Main Engine Test" that NASA conducted with each new Orbiter and prior to the STS-26 flight.

- It would be expensive, time-consuming, and weight-intensive to convert the ground-started SSME to an air-started version for the Ares I second stage.

With several design changes to the Ares I and Ares V rockets, the SSME will be replaced with a single J-2X engine for the Ares I second stage. The Ares V will use six modified RS-68 engines (which was based on both the SSME and Apollo-era J-2 engine) for its core stage. Hence the SSMEs will be retired along with the Shuttle fleet.

NASA may retain all SSMEs[9] for possible reuse. One source suggests that unlike Endeavour and Atlantis,[10][11] they are not available for donation as display pieces.[9] Another source said they would be given away for free.[8]

NASA was directed in the fall of 2010 to stop Project Constellation, and among other goals, focus on building a new heavy lift launcher.[12]

Future plans

Szablon:As of, NASA intends to retain 14 to 16 of the Block II reusable SSMEs, and preserve them for possible use in some yet-to-be-defined follow-on program. The engines will be stored in a "purged safe" environment, "along with all of the ground systems required to maintain them."[3]

At one pointSzablon:When NASA had plans to sell the engines, and thenSzablon:When to give them away for free when the program ends.[8]

Alternatively, NASA proposedSzablon:When keeping the engines for a Heavy Lift Vehicle, including a recommendation to replace real engines on donated orbiters with replicas from spare parts.[13] Project Constellation was canceled in October 2010, however NASA negotiated HLV studies from 13 companies in November 2010.[12][14]

Specifications

Nozzle

The SSME nozzle diameter was 10,3 in (0,26 m) at the throat and 90,7 in (2,30 m) at the nozzle exit, with a length of 121 in (3,1 m).[15]

General

Specifications as listed in the Encyclopedia Astronautix[potrzebny przypis]

- Engine Model: SSME

- Manufacturer Name: RS-25

- Other Designations: RS-24

- Designer: Rocketdyne

- Developed in: 1972

- Propellants: Lox/LH2

- Thrust(vac): [convert: niepoprawna liczba]

- Thrust(sl): [convert: niepoprawna liczba]

- Isp: 453 s

- Isp (sea level): 363 s

- Burn time: 480 s

- Mass Engine: 3,177 kilograma (7,00 lb)

- Diameter: 1,63 metra (5,3 ft)

- Length: 4,24 metra (13,9 ft)

- Chambers: 1

- Chamber Pressure: 204,08 bar (2 959,9 psi)

- Area Ratio: 77.50

- Oxidizer to Fuel Ratio: 6.00

- Thrust to Weight Ratio: 73.12

- Country: USA.

- Status: In production

- First Flight: 1981

Other specifications as previously[potrzebny przypis] listed on Wikipedia:Szablon:Verify credibility

- Design altitude: 60 000 stóp (18 300 m)

- Nozzle Mach number: 6.55 (ideally expanded) (4.7 calculated via expansion ratio and frozen gamma of 1.20)

- Throat area: 93 cale kwadratowe (600 cm2)

- Nozzle area: 50,265 stopy kwadratowej (4,6698 m2)

- Chamber pressure: 2 747 pounds per square inch (18 940 kPa) at 100% power

- Exit pressure: 1,049 pounds per square inch (7,23 kPa) (calculated) (calculated value based on 490850 lbf of thrust and roughly 7 200 cale kwadratowe (4,6 m2) of nozzle area, dynamic exit pressure was more like 68 pounds per square inch (470 kPa) absolute)

- Burn time: 520 s

- Vacuum Isp: 452.5 s

- Vacuum thrust per engine: 490 850 funtów siły (0 MN) at 104.5% of design thrust

Missions

Based on a P&W handout, SSME missions up to 2006:[2]

- SN-2005 5

- SN-2006 5

- SN-2007 5

- SN-2011 7

- SN-2012 22

- SN-2015 9

- SN-2017 14

- SN-2018 12

- SN-2019 19

- SN-2020 6

- SN-2021 6

- SN-2022 8

- SN-2023 5

- SN-2024 7

- SN-2026 6

- SN-2027 7

- SN-2028 11

- SN-2029 15

- SN-2030 10

- SN-2031 17

- SN-2032 7

- SN-2033 9

- SN-2034 9

- SN-2035 3

- SN-2036 3

- SN-2037 5

- SN-2038 3

- SN-2039 4

- SN-2040 4

- SN-2041 5

- SN-2042 3

- SN-2043 7

- SN-2044 7

- SN-2045 8

- SN-2047 6

- SN-2048 4

- SN-2049 7

- SN-2050 5

- SN-2051 4

- SN-2052 5

- SN-2053 5

- SN-2054 6

- SN-2055 1

- SN-2056 6

- SN-2057 1

- SN-2107 5

- SN-2109 17

Zobacz też

- MPTA-098 - przedmiot testów używany w czasie prac rozwojowym nad STS

- Rakieta dodatkowa na paliwo stałe - używana w czasie wynoszenia dla uzyskania dodatkowej mocy

- RD-0120 - analogiczny silnik rakietowy stosowany w systemie startowym Energia

Źródła

- NASA Shuttle Press Kit SSME Reference.

- Space Shuttle Main Engine.

- Space Shuttle Main Engine Enhancements.

- The Roar of Innovation.

- Space Shuttle Main Engine - incredible facts.

- Space Shuttle Main Engine The First Ten Years.

- NSTS 1988 News Reference Manual.

- "Boeing Liquid Propellant Rocket Systems", Rocketdyne Propulsion & Power, Pub. 573-A-100 9/99, page 26.* Encyclopedia Astronautix, reference SSME / RS-24.

Linki zewnętrzne

- ↑ Błąd w składni szablonu {{Cytuj stronę}}. Brak podanego tytułu cytowanej strony (parametr tytuł=|).

- ↑ a b KSC booklet, Quote: "Since the first Space Shuttle launch on April 12, 1981, 42 different SSMEs have successfully demonstrated the performance, safety, and reliability of the world's only reusable liquid-fuel rocket engine.", source

- ↑ a b Szablon:Cite news

- ↑ Nozzle Design

- ↑ http://www.hq.nasa.gov/office/pao/History/computers/Ch4-7.html

- ↑ http://www.hq.nasa.gov/office/pao/History/computers/Ch4-8.html

- ↑ http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19930012456_1993012456.pdf

- ↑ a b c d e Szablon:Cite news

- ↑ a b Błąd w składni szablonu {{Cytuj stronę}}. Brak podanego tytułu cytowanej strony (parametr tytuł=|).

- ↑ Szablon:Cite news

- ↑ Błąd w składni szablonu {{Cytuj stronę}}. Brak podanego tytułu cytowanej strony (parametr tytuł=|).

- ↑ a b Szablon:Cite news

- ↑ Chris Bergin - Replica engines recommended for retired orbiters – Flown SSMEs for HLV (October 21st, 2010) - nasaspaceflight.com

- ↑ RELEASE : 10-292 NASA Selects Companies For Heavy-Lift Launch Vehicle Studies

- ↑ Błąd w składni szablonu {{Cytuj stronę}}. Brak podanego tytułu cytowanej strony (parametr tytuł=|).

Kategoria:Promy kosmiczne Kategoria:System Transportu Kosmicznego